|

|

|

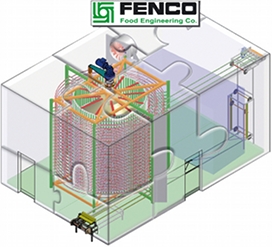

Fruits Vegetables Freezing Equipment

Twist Freezer for Fruits &

Vegetables

Cost effective solutions, outstanding quality and reliability

are common for Fenco food processing machines.

MAIN FEATURES:-

- TWIST FREEZER is particularly designed in accordance to the

customer needs of "taylor made solution".

- Very high mechanical reliability of spiral belt conveyor.

- Reduced belt wear and elongation thanks to low tension

drive system (the belt is pulled by means of dynamic friction on the

total length).

- Belt system lubrication is free of any possible risk of

product contamination.

- Long work cycles due to "symmetrical" large fins spacing

design on the air entrance, and oversizing of evaporator.

- Possibly to have bi-directional "clockwise, and counter

clock wise" air flow in the evaporator "efficiency", having

automatically longer running cycle.

- TWIST FREEZER is designed as "Easy Clean" concept avoiding

point of dirtiness accumulation.

- TWIST FREEZER has as standard ventilation the "VOT" concept

"horizontal tangential type" air flow.

- Low maintenance cost, and low spare parts cost due to the

use of high quality commercial components.

- Belts and drum gear motors positioned outside the insulated

cabin, avoiding any risk of contamination due to some oil leakages.

- Central Drum drive supported by roller bearing.

- Stainless steel flexible belt or plastic belt for special

application such as sticky or tender products with low water content

products.

- Spiral structures made of stainless steel.

- Low pressure fans to increase air speed and heat exchange.

- Flat tin evaporators with low air pressure drop.

- Fully automatic washing system (option) with lose water.

- C.I.P. "Cleaning in Place" system with the possibility to

use basic - acid - detergent and disinfectant solutions (option).

- PLC and touch screen supervision system (option).

- Ice Extraction Belt "Patented" (option), positioned just on

top of the evaporator, which assure a continuous run minimum 48 hours

between each defrosting cycle, with the possibility to work up to 72 -

120 hours in accordance to the type of product and the environmental

conditions.

CONTINUOUS AIR FILTERING

SYSTEM Mod. SFA

Concept:-

Applied in a freezer is a solution that provides to keep as much as

possible the recycled air free from moisture - ice, and from product

flying particles during the freezing operations.

Ice is generated due to the water - moisture losses coming from the

products (evaporation) and from the incoming air during the product

feeding - loading.

Quantity of products flying particles varies in accordance with the

type of products, on process.

Usually ice and products flying particles are captured in the inner

parts of the freezer, and mainly into the coils - evaporators.

With the increasing of ice accumulation into the coils - evaporators,

the efficiency of those units will drop drastically, then usually to

maintain the same efficiency - performances a higher power consumption

is needed.

As consequences periodically the freezer needs to be stopped for the

de-frosting operation, with considerable drop page in the production

with a certain increase of the operative costs.

SFA concept and application will improve the following:-

- - Considerable increase of the freezing cycle and

production.

- - Minimising the number of stoppages and defrosting cycles,

with much lower operational costs.

- - Minimising the energy consumption needed to obtain the

final results.

- - Improvement of the final product quality, while the

frozen product is almost free from ice on its surface (this is

particularly appreciate for the products which are packed in a

transport packages).

Application:-

SFA is a mesh wire conveyor positioned all around the coil -

evaporator, and because of this is acting as continuous air filter.

It runs for the full length of the freezer, with an outside extension

to discharge the ice - end product particles out of the freezer chamber.

The mesh is continuously cleaned - blow and dry before coming back into

the cabin, it is possible to have also a water cleaning system in case

of more demanding cleaning operation (optional).

The air flow pass first through the product and then to the SFA before

it reaches the evaporators. The mesh filters will capture the majority

of the ice - frost, and product debris. The freezer therefore remains

relatively free with much longer freezing efficiency - production. As

consequence the coils - evaporator surface will remain more cleaner

giving better performance.

With this system the stoppages due to defrosting - cleaning and machine

sanitation will be drastically reduced by approx. 50 - 80% , subject to

the type of product.

Averages:-

- Minimum defrost cycle:- 48 hours "guaranteed"

- Nominal defrost cycle:- up

to 72 - 120 hours

- (subject of product type and environmental

conditions).

This is Fenco "patented" solution.

Complete turnkeys packaging

solutions are available on request.

Please contact us on info@jzw.com.au to discuss your application. |

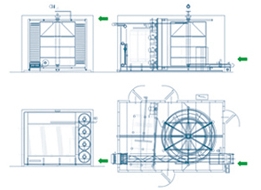

Twist air cooler cubicle

Fruits and

vegetables

Twist freezer spirals air flow

Twist freezer

spiral

Twist freezer spirals

air flows

Fruits

vegetables packages

|