|

|

|

Fruits Vegetables Processing

Fruits and vegetables pressure steam peeler -

Fenco

Food Engineering is a company established in Italy in 1984 and well

known as manufacturer of food processing machinery and complete food

processing and packaging lines.

GENERAL FEATURES

- Approved steel pressure container, operating at 15 Ate with

saturated steam.

- Inner revolving container made of perforated stainless

steel plate for production input.

- Automatic weighing device to weigh the product.

- Spent steam, condensate and peal collection tank.

- Supporting frame with ladder and catwalk made of stainless

steel.

- Electronic pannel IP 55 with PLC to program automatic

operating cycles.

- Steam peelers have almost entirely replaced chemical

peeling systems, which caused pollution, generated high running cost

and unsatisfactory quality of the peeled product.

FENCO have improved steam peeling technology considerably by

introducing new SBS series of steam peeling equipment.

By means of the double tank and by creating vacuum before closing the

pressure steam tank exceptional advantages have been obtained:-

- - reduced exposure to high temperatures with minimal

surface burning;

- - delicate treatment of the product obtained by the

rotation of the container along its main axle;

- - continual separation of the condensate, with better use

of the steam.

- - less pollution of the product caused by parasiticides in

the peel because the condensation and the peel fragments are

continually drained away from the peeled product.

- - better exposure of the product to steam as steam comes

from the inside and from the outside of the wall at the same time.

- - extremely low unloading times.

- This machine can also be used for steam cooking of a wide

range of products.

Complete turnkeys packaging solutions are available on request.

Please contact us on info@jzw.com.au to discuss your application.

|

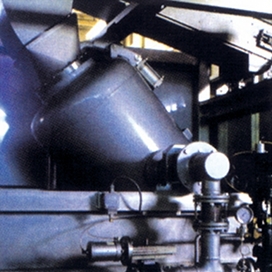

Fruits and vegetables pressure steam

peeled

Fruits and vegetables pressure steam

peeler

Fruits and vegetables pressure steam

peeled

Loading of fruits and vegetables

pressure steam peeler

Fruits and vegetables pressure steam peeled

|