|

|

|

Fruits Vegetables Pasteurising & Cooling

Equipment

Twist Air Pasteuriser and Cooler Spirals

for Fruits &

Vegetables

Cost effective solutions, outstanding quality and reliability

are common for Fenco food processing machines.

Why

TAP & TAC solution

The "TAP & TAC" TWIST AIR

PASTEURISER - COOLER

is a reliable alternative solution to the traditional linear

"pasteurising and cooling tunnel" working with water, at different

temperatures, etc.

The "TAP & TAC" solution

is particularly indicated whereas:-

- Water is not available or very costly.

- In the dry ambient where water can create troubles in the

production and/or in the environmental conditions.

- Absolutely water free consumption.

- Very easy and friendly cartoning - packaging operation in

line, with risks of water damages in the final pallet.

- Less maintenance cost, due to the less parts / components

in motion as "wear and tear" compared to traditional tunnel.

- Huge useful surface available compared to the traditional

linear tunnels.

- Factory space saving compared to traditional linear tunnels.

- Possibility to change working level - floor during the same

processing phases - cycles.

- Minimising and / or optimising the production costs due to

the continuous operation - running cycles, and lower manpower involved.

- Possibility to treat different type of products and / or

packed products in the same time - on the same belt.

- Final product standardisation.

TAP & TAC applications

The "TAP & TAC" can find

easily applications into:-

- the traditional preserved food like fruits, or vegetables.

- in the pasta production, for "stabilised" long shelf type

pasta.

- meat industries.

- ready meals sector.

- bakery products.

- sweet bakery products.

- chemical, or pharmaceutical industries.

- etc.

Main

concept

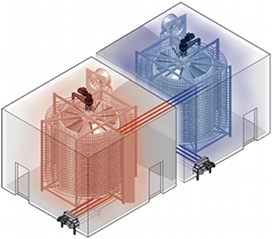

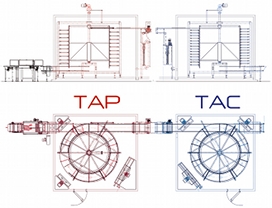

The "TAP & TAC" TWIST AIR

PASTEURISER - COOLER here included basically is solution made by

a "twin" spiral conveyors where the:-

"Pasteurisation

cycle" take place in the 1st spiral.

and

"Cooling cycle" take place in

the 2nd spiral.

- Each spiral is located inside an insulated cabin made out

of sandwich panels, specifically designed for each application TAP

- TAC working conditions.

- The chambers are positioned keeping a certain distance in

the between to avoid interferences and / or any "Thermal Bridges".

- Both system are using either "Hot Air", or "Cold Air" recycle

air flow.

- "Hot Air". or "Cold Air" are generated trough heat

exchangers using steam or Freon/Ammonia.

- In case of special packaging and / or products the passages

between the two belt is provided by a smooth passage thanks to "pen

type belt".

- Belt's can be in flexible stainless steel type or in

modular flexible plastic material, upon specific preferences and

applications.

- In order to obtain the quickest and the most efficient

thermal process TWIST AIR PASTEURISER

- COOLER is designed for:- -air

speed circulation (4 - 10 m/sec) of hot and cold air in the chambers.

Specific

configuration

Upon specific application "TAP & TAC" can be

provided with:-

- HMA "High Moisturised Air",

mainly in the TAP

chamber, in order to improve the thermal exchange and minimise the time.

- due to some particular locations TAC can have A/C

design, that allow to have a double cooling circuit, using external

ambient air in the 1st half, and a refrigerated air in the 2nd half for

the final cooling. This configuration depends on the type of product

and to the geographical and weather conditions, but when ever this

application can take place give a big saving in terms of production

cost, and energy savings,

- Through this combination we can obtain the following

effects:-

- higher thermal exchange on the product surface.

- quicker and faster thermal "hot and cold" penetration.

- due to this the quality of the final product is not

particularly affected and it's final characteristics are like the fresh

one, and mostly with minimum risks of having "brownish and / or

cooked" final products.

- Standardisation of the final products.

Main

design

The "TAP & TAC" solution

reassume the conditions and the parameters needed to approach correctly

the modern food industry.

Machine design concept applied in this unit is the:-

* Easy Clean Design - our code

EC

- The unit doesn't have any mezzanine floor and / or

intermediary platform, to avoid any excess of point where dirtiness can

accumulated making more difficult the cleaning operations.

- Drum is without lateral openings to improve the air

guidance and to minimise the possibility to accumulate dirtiness, in

the point where access is not easy if not possible.

- Central Drum drive supported by roller bearings.

- Stainless steel flexible belt, or plastic belt for special

application such as sticky, or tender products with low water content

products.

- Spiral structures made of stainless steel.

- Very high mechanical reliability of spiral belt conveyor.

- Reduced belt wear and elongation thanks to low tension

drive system (belt is pulled by means of dynamic friction on the total

length).

- Machines design "maintenance free".

- Low maintenance cost, and low spare parts cost due to

utilisation of high quality commercial components.

- Machine design "lubrication free".

- No possibility of product contamination.

- Belt and drum driving gears usually positioned outside the

insulated cabin, avoiding any risk of contamination due to some oil

leakages.

- PLC with touch screen supervision system.

- All mechanical parts are in stainless steel, food grade

plastic materials, special anodised aluminium.

Air flow concept applied in this units is the:-

* Horisontal Tangential Ventilation

type our code VOT

- The lateral aprons to guide the airflow on the opposite

side of the evaporators are on easy access design like door openable or

sliding, but in any case easy access is granted all around.

- Possibility to have bi-directional air flow due to the

special axial reversible fans.

- Axial fans to optimise the energy consumption.

- Flat fin evaporators - heat exchangers with low air

pressure drop with decreasing flat fins spacing.

- Heat exchanger are usually either in stainless steel,

aluminium, copper, galvanised steel (upon specific applications and /

or as per customer preferences).

As consequences we can obtain:-

- Longer working cycle due to:-

- THE EVAPORATOR DIMENSIONS AND DESIGN WITH DECREASING

SPACING.

- VERY LOW THERMAL LOSES IN THE RECYCLE AIR FLOW.

- As (option) we can provide "symmetrical"

bi-directional air flow design evaporators on the air entrance assuring

the same performance even once we revert the air flow. This solution is

particularly appreciate in the factory which are working only

seasonally, and provide quite long running time delaying the stoppages

due to the defrost cycle, increasing enormously the daily production.

Complete turnkeys packaging

solutions are available on request.

Please contact us on info@jzw.com.au to discuss your application. |

Twist air pasteuriser cooler cubicles

Fruits and

vegetables in tabs

Twist air pasteuriser cooler air flow

Twist air

pasteuriser cooler

Twist air

pasteuriser cooler

Fruits and vegetables

cooled by twist air cooler

Twist air

pasteuriser cooler food

Air colled

fruits vegetables packages

Air colled

fruits vegetables packages

Air

pasteurised colled

vegetables

Pasteuriser

cooler spirals

Air

pasteurised colled

vegetables

Air

pasteurised colled

vegetables

Air

pasteurised colled

vegetables

|